Advanced manufacturing technologies

The Advanced Manufacturing Technologies (AMTECH) research group of the Politecnico di Torino deals with research topics related to production technologies. Conventional manufacturing processes are studied for optimization and development of more advanced applications. Unconventional machining and additive technologies (Additive manufacturing – AM) have been investigated from the early years in which they emerged in the production scenario. The research activities developed during the last years cover AM applications in many industrial sectors, from aerospace to automotive industry, from biomedical to jewelry field. The AMTECH research group has specific skills in the areas of virtual manufacturing, Reverse Engineering (RE), Computer Aided Manufacturing (CAM) and contactless inspection of tools and products.

The main research areas currently under investigation are summarized in the following:

-

Additive Manufacturing (coordinator Prof. Luca Iuliano)

Our research activities are focused on the application of additive techniques and thus on the analysis of existing processes in terms of process optimization, part quality improvement and new applications or future perspectives from the point of view of final users and new adopters of additive technologies. Over the years the AMTECH Group has gain considerable expertise in the field of with re-design for AM of parts made of plastic and metal materials, also by exploiting the benefits of topology optimization tools. As regards the production of metal parts, we investigated the mechanical performances and geometric potentialities linked to limitations related to support structures. Techniques to improve the surface finishing of AM parts are under investigation as well and a benchmarking activity is on going to compare the performances of different systems from the point of view of part’s dimensional accuracy. -

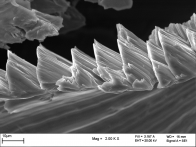

Sustainability of Manufacturing Processes (coordinator Prof. Luca Settineri)

The activities of the second track are centered on the sustainability of the manufacturing processes. In particular, they focus on the optimization of the manufacturing processes from the points of view of the economic, environmental, social and health sustainability, with a perspective extended to the whole manufacturing cycle of the product and inclusive of the machine tools and the production systems. The processes are here studied with a viewpoint of comparison and integration.

For both above mentioned research topics, our competences cover the analysis and optimization of manufacturing processes in terms of:

- process design;

- influence of process parameters;

- evaluation and analysis of the response variables on the process and product;

- process simulation through CAD/CAM/CAE software tools;

- evaluation of part quality in terms of superficial roughness, dimensional accuracy and deviations, GD&T tolerances both from a micro and macro point of view;

- comparative analysis of the manufacturing cycles in view of the economic, environmental, social and health sustainability;

- manufacturing process optimization from the standpoint of process integration.

Selected funded research projects

-

Definizione di una procedura numerica per la progettazione del processo di imbutitura in lamiera

Sheet-metal forming | Process simulation

C.L.N. Group S.p.A - MA S.r.l., Magnetto Automotive -

Studio e applicazione della tecnologia additive manufacturing applicata a parti meccaniche di gimbal e apparati per applicazioni avioniche

Additive Manufacturing | Design for Additive Manufacturing

Elettronica Aster S.p.A -

Cluster Fabbrica Intelligente – High Performance Manufacturing

Additive Manufacturing | Topology optimization

SPEA S.p.A -

Integration of additive manufacturing and machining processes in view of green and sustainable development - IntegraGreen (Alta Scuola Politecnica)

Sustainable manufacturing | Process integration

APR S.r.l. - Politecnico di Milano -

Lavorazioni Meccaniche Eco-Compatibili per Materiali Difficili (LavoEco)

Machining | Eco-friendly production systems

Novatea S.p.A. - Osvat S.r.l. - UFS S.r.l. - Università di Torino - Environment Park S.p.A. - Wolframcarb S.p.A.

Keywords

- Additive Manufacturing

- 3D Scanning

- Process simulation

- Machining/Cutting

- Sustainability in Manufacturing

Research staff